In today’s fast-paced industrial landscape, the integration of Artificial Intelligence (AI) and digital twin technology is revolutionizing how warehouses and manufacturing facilities operate.

Younite’s innovative approach to AI-driven pallet tracking using digital twins has had a strong impact on warehouse logistics, offering real-time visibility, optimized layouts, and enhanced inventory management. This foundational solution is not only reshaping warehouses but also holds immense potential for broader applications across various manufacturing and factory environments.

The Younite Approach

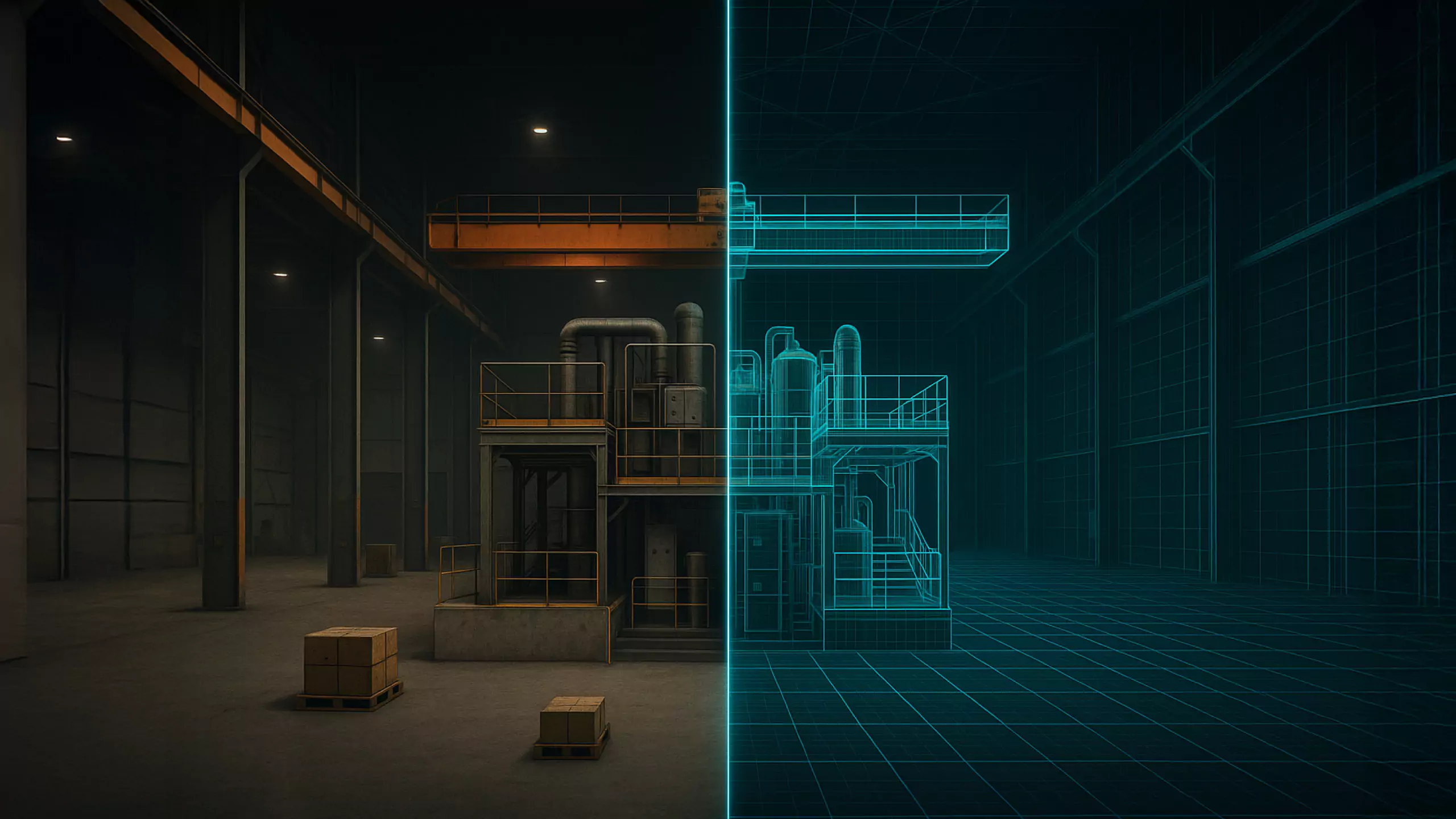

Younite’s methodology involves creating a photorealistic digital replica of a warehouse using platforms like NVIDIA Omniverse. This digital twin serves as a dynamic environment where AI models are trained through simulated scenarios, such as pallet movements and storage patterns. Once validated, these AI models are deployed in the real world, utilizing strategically placed cameras to track pallets in real-time, thereby eliminating manual interventions and reducing errors .

Expanding Horizons: Applications Beyond Warehousing

The principles underpinning Younite’s work can be extrapolated to various manufacturing and factory settings:

- Production Line Optimization: Digital twins can simulate and analyze production workflows, identifying bottlenecks and optimizing processes for increased efficiency.

- Predictive Maintenance: By continuously monitoring equipment through digital twins, potential failures can be anticipated and addressed proactively, minimizing downtime.

- Facility Layout Planning: Virtual models allow for testing different factory layouts, ensuring optimal space utilization and workflow before physical implementation.

- Training and Safety: Digital twins provide immersive training environments for employees, enhancing safety protocols and operational understanding without disrupting actual operations.

Business Impact: Driving Efficiency and ROI

Implementing AI-driven digital twins across manufacturing environments offers tangible benefits:

- Cost Reduction: Automation of tracking and monitoring processes decreases labor costs and minimizes errors.

- Enhanced Decision-Making: Real-time data and simulations provide actionable insights, facilitating informed strategic decisions.

- Scalability: Digital twins can be scaled across multiple facilities, ensuring consistency and standardization in operations.

- Sustainability: Optimized processes lead to reduced waste and energy consumption, aligning with environmental goals.

Conclusion

Younite’s AI-driven digital twin technology, initially designed for warehouse logistics, presents a versatile and impactful solution for the broader manufacturing sector. By embracing this approach, industries can achieve significant improvements in efficiency, cost savings, and operational excellence.

For more information on how Younite’s solutions can transform your operations, visit Younite.ai.

DIGITAL TWIN • INDUSTRIAL AI • INSIGHTS

AI in warehouse logistics: AI-driven pallet tracking with digital twins

NEWS • NVIDIA • PRESS RELEASES